Biggs Tool & Die, Inc. is committed to achieving customer satisfaction by providing quality products that are delivered on time. We accomplish this through the use of efficient processes and the continual improvement of our system. As a means to ensure product conformance, specified requirements and continued compliance to ISO 9001:2015 and AS9100D, a company–wide quality system has been established, documented, implemented and maintained by the management of Biggs Tool & Die, Inc. This system has been implemented at all levels: from the beginning of the quoting process, through the production of part to the final delivery. Product conformity and on time delivery performance are measured and appropriate action is taken if planned results are not or will not be achieved.

In the course of developing this documented quality management system, Biggs Tool & Die, Inc. has determined the necessary processes, their application and sequences of interaction. Biggs has defined methods for evaluating the effectiveness of these processes through our quality policy, management review and analysis of data. Our staff monitors, measures and analyzes these processes of production to ensure efficiency and customer satisfaction. All employees understand the importance of the system implementation and how important it is for them to make suggestions that can help achieve further improvement of quality controls.

Biggs has established corrective and preventive actions for continual improvement.

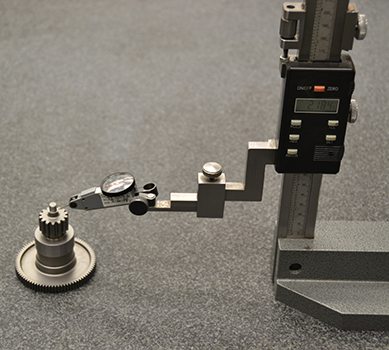

Inspection Department Equipment - CMM

- (1) Mitutoyo CRYSTA-APEX S776 w/ Gear Pak -- Fully Programmable

- (1) Sheffield Cordax 1808 M CMM with Quadra – Chek 300

- (1) Helmel MicroStar CMM with Quadra – Chek 300

- (1) Mitutoyo SPC Digimatic Mini-Processor DP-IDX

- (1) J & L 14” Optical Comparator with SPC Capabilities

- (1) Mitutoyo 24” Digital Height Gage with SPS Capabilities

- (1) Microvue Optical Comparator with MD-1 Digital Read Out

- (1) Wilson Hardness Tester

- (4) Complete Sunnen Bore Gaging System

- (1) Complete Set Gage Pins up to 1.000 Diameter

- Starrett Super Micrometer — 0.000” – 2.000”

- Fully Stocked Gage Pins

- Fully Stocked Thread Gages